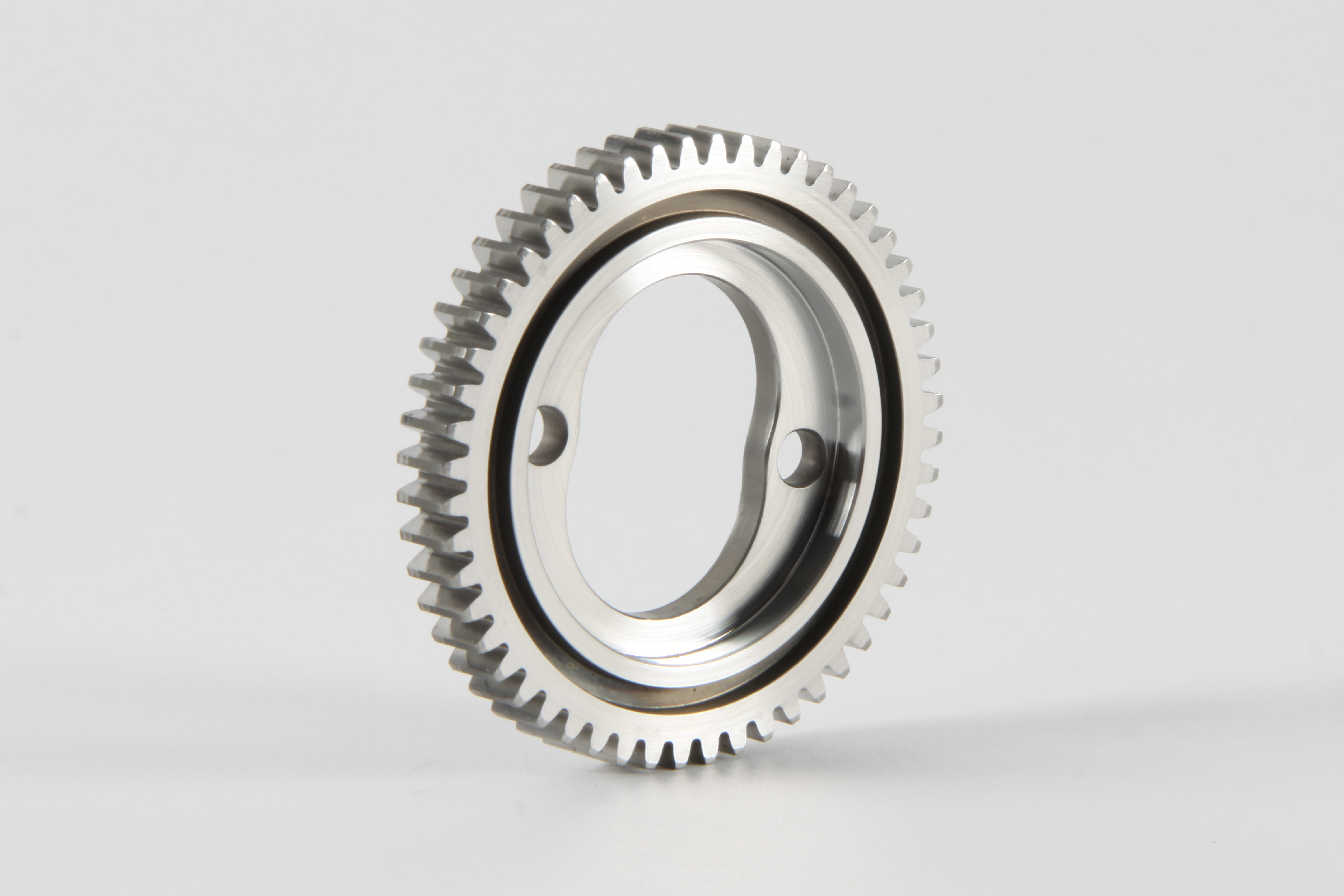

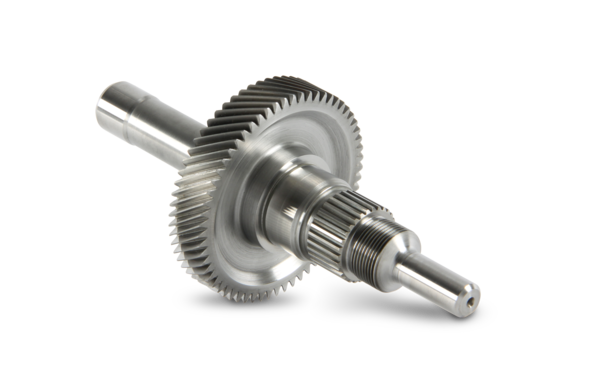

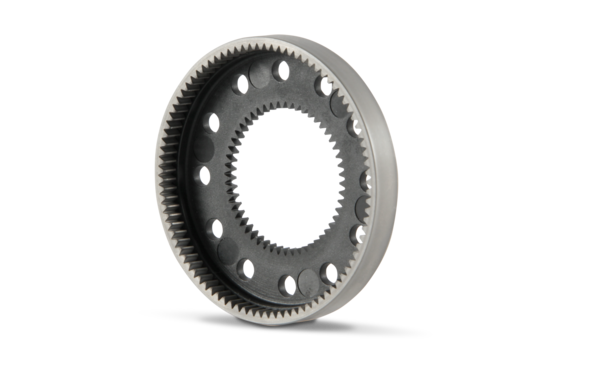

Gears from KOEPFER.

The growing demand for fuel efficient engines and drive systems has also had an impact on the requirements for gears for engine control. This in turn has a direct effect on production: new materials, new geometries, and therefore new workpieces with very high requirements in terms of quality and products.

With our existing production expertise and the technologies at our disposal, KOEPFER can offer an economical solution for virtually any production requirement. In particular, we have many years of experience in the field of production and assembly of machined system units.

With additional processing stages, we are able to make gears that produce very little running noise in operation. By means of an additional noise check, we ensure that the quality values required are always met.

Images:

Gears from KOEPFER.

With the highest level of process expertise in manufacturing, we can produce gears in very large quantities and with absolute dimensional accuracy. Over 15 million gears of the highest quality are manufactured every year at our production sites in Furtwangen, Bräunlingen, and Ludwigsburg.